Life Cycle Assessment (LCA) of Organic Cotton Clothing: A Complete Guide

Introduction

We all love the idea of organic cotton, often marketed as the sustainable alternative. But to get the real environmental story behind these fibers, we conduct Life-Cycle Assessment (LCA) upon customers’ request to support their sustainability goals. By using LCA with our partners at Green Story, we track the full journey of a garment: from seed to shelf and beyond. This kind of analysis helps brands and consumers cut through buzzwords and take actionable steps toward true sustainability.

LCA is a scientific method for evaluating the environmental impacts of a product throughout its life cycle: from raw material extraction (“cradle”) to disposal or recycling (“grave”). For our sourcing, we examined every step: farming, ginning, spinning, weaving or knitting, dyeing, garment manufacturing, to final transportation. While we haven’t yet investigated use and end of life, it’s also important in the long term and a step we’re considering.

By examining the results and identifying “hotspots” of environmental impact, LCA provides a roadmap for improvement and a foundation for credible sustainability claims.

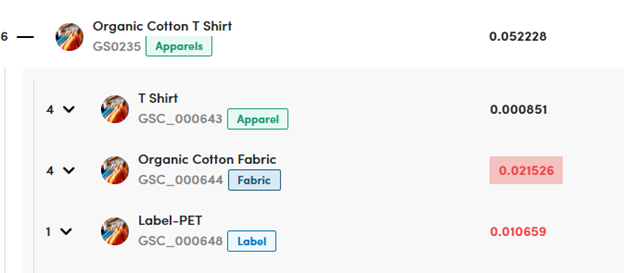

Example hotspot view via GS platform.

1. What Is Life Cycle Assessment (LCA)?

LCA is rooted in the global ISO 14040/44 standard. There are four key phases:

- Goal & Scope Definition – What are we measuring, and where do we draw the line?

- Inventory Analysis – Gathering data on inputs (e.g., water, energy, raw materials) and outputs (e.g., emissions, waste).

- Impact Assessment – Turning that data into environmental indicators like GHG emissions or water use.

- Interpretation – Pinpointing hotspots and shaping strategies for improvement.

2. The LCA View of Organic Cotton

Verified organic cotton avoids synthetic pesticides, herbicides, and GM seeds. This can lead to several upsides from an environmental perspective:

- Lower chemical use – Reduced harm to ecosystems and farmer health.

- Soil health improvement – Organic farming methods like crop rotation, composting, and reduced tillage enhance biodiversity and soil fertility.

- Water conservation – Many organic farms rely more on rain-fed irrigation.

- Lower greenhouse gas emissions – Avoidance of synthetic nitrogen fertilizers cuts nitrous oxide emissions.

Depending on the region and farming practices, organic cotton can sometimes produce lower yields per acre compared to conventional cotton, and LCA helps quantify the trade-offs and give that complete picture.

3. Life Cycle Stages of Organic Cotton Clothing by Inputs and Impacts

a. Cultivation

- Inputs: Organic seeds, compost or manure-based fertilizers, natural pest control methods, irrigation (often rain-fed). Gallant’s ongoing organic cotton project in Odisha relies on rainfed cultivation.

- Impacts: Lower toxicity, improved soil health, but potentially higher land use per unit output.

- Process: Separating cotton fiber (lint) from seeds.

- Impacts: Energy use, typically lower than spinning or dyeing, but still relevant in regions dependent on fossil-fuel electricity.

b. Ginning

c. Spinning

- Process: Converting lint into yarn.

- Impacts: High electricity demand for machinery. Renewable energy adoption here can cut emissions significantly.

d. Weaving and Knitting

- Weaving – Interlacing warp and weft yarns to create woven fabrics used in shirts, pants, and jackets.

- Knitting – Looping yarns to create knitted fabrics for T-shirts, sweatshirts, and activewear.

- Impacts:

- Energy use – Weaving tends to consume less energy than knitting, but knitting machines may run continuously for high output.

- Waste – Both processes can produce waste yarn or offcuts.

- Efficiency gains – Using energy-efficient looms/knitting machines, optimizing layouts, and reusing waste yarn reduce impacts.

e. Dyeing and Finishing

- Process: Coloring fabrics using GOTS-approved low-impact dyes, then applying finishes (e.g., softening, wrinkle resistance).

- Impacts: One of the highest water and energy use stages. Dye bath heating, multiple rinses, and drying contribute to emissions.

- Improvements: Low-liquor ratio dyeing, closed-loop water recycling, natural dyes. It’s often the phase that a lot of products focus on first given its high impact.

f. Garment Manufacturing

- Process: Cutting, sewing, assembling garments, adding trims, and packaging.

- Impacts: One of the highest water and energy use stages. Dye bath heating, multiple rinses, and drying contribute to emissions.

- Process: Moving products through the supply chain to retailers and customers.

- Impacts: Air freight has the highest emissions; sea freight is lower but slower.

- Solutions: Consolidated shipments, regional production, low-carbon transport modes. It’s impact is often inflated and overstated. While air freight has one of the highest carbon impacts per ton-kilometer, most apparel companies outside of fast fashion use it sparingly—often less than 5% of total freight volume—relying instead on lower-impact modes like sea or rail.

g. Distribution

h. Use Phase

- Process: Washing, drying, and ironing by consumers.

- Impacts: Over a garment’s lifetime, consumer care can account for 30–50% of total emissions.

- Solutions: Encourage cold-water washing, line drying, and reduced ironing.

- Options: Reuse, recycling into new textiles, composting (for 100% organic cotton), or landfill.

- Impacts: Landfilling contributes to methane emissions; recycling reduces virgin fiber demand.

i. End-of-Life

4. Benefits of Organic cotton fiber over Conventional cotton from LCA Studies

According to C&A Foundation (2019), study compared to conventional cotton, organic cotton has:

- 74% lower CO₂ emissions

- 61% lower blue water consumption

- 69% lower primary energy demand.

- 79% less acidification potential.

However, the product LCAs also reveal that spinning, knitting/weaving, and dyeing are major contributors to carbon and energy footprints, even in organic cotton based products

5. How LCA Helps Clothing Brands

- Identify impact hotspots – e.g., high water use in dyeing, high carbon footprint in air transport.

- Set sustainability targets – measurable goals like "reduce dyeing water use by 30%."

- Back sustainability claims – with verified data, avoiding greenwashing.

- Engage suppliers – in collaborative improvement projects.

LCA empowers brands to:

6. Strategies to Reduce Impacts Identified by LCA

At the farm level:

- Promote regenerative organic methods for soil carbon sequestration.

- Support farmer training in water management and natural pest control.

At the ginning, spinning, weaving, and knitting stages:

- Invest in renewable energy sources (solar, wind).

- Upgrade to high-efficiency looms and knitting machines.

- Reuse production waste.

At dyeing and finishing:

- Adopt low-liquor dyeing machines.

- Implement wastewater treatment and recycling systems.

At garment manufacturing:

- Use pattern optimization to minimize offcuts.

- Switch to compostable or recycled packaging.

In distribution:

- Consolidate shipments, use sea freight over air where possible.

In consumer use phase:

- Provide garment care labels promoting cold washing and line drying.

At end-of-life:

- Establish take-back and textile recycling programs.

7. The Role of Certifications

Certifications such as GOTS (Global Organic Textile Standard), Fairtrade, and Regenerative Organic Certified® (ROC) work alongside LCA:

- LCA measures environmental performance quantitatively.

- Certifications verify that social, environmental, and ethical criteria are met.

Conclusion

Life Cycle Assessment reveals the full story of a garment’s environmental footprint, from seed to shelf and beyond. For organic cotton clothing, LCA confirms clear benefits over conventional cotton in chemical use, water conservation, and emissions reduction. However, significant impacts remain in energy-intensive stages like spinning, knitting/weaving, dyeing, and consumer care.

By acting on LCA findings, brands can make targeted improvements — such as transitioning to renewable energy, optimizing logistics, and designing garments for longevity and recyclability. Combined with strong certifications, LCA ensures that organic cotton clothing is not just better for the planet in theory, but demonstrably sustainable in practice.

For more information, please contact:

Vik Giri

Akhil Sivanandan

Sources / Credits

Life Cycle Assessment of Cotton Cultivation Systems: Better Cotton, Conventional Cotton and Organic Cotton, C&A Foundation, 2019.

Global Organic Textile Standard (GOTS) – www.global-standard.org

Regenerative Organic Certified® – www.regenerativeorganic.org